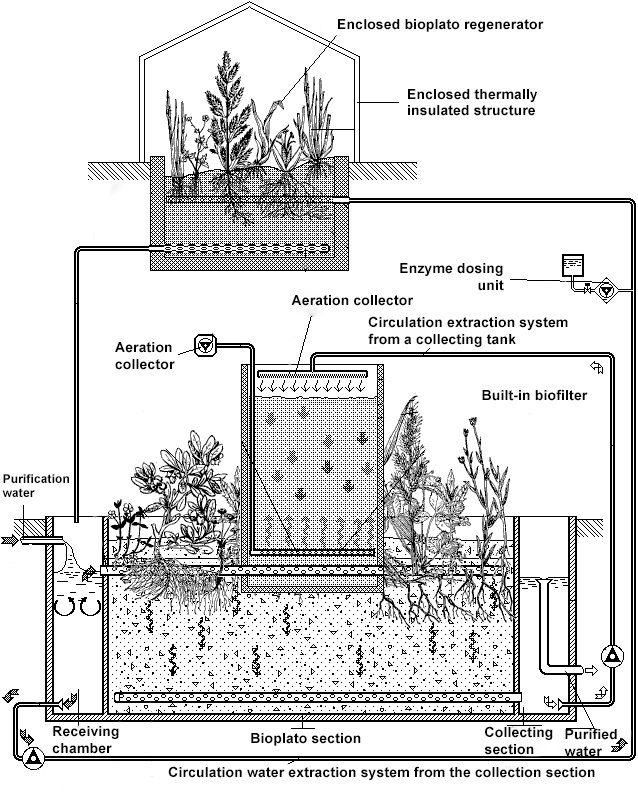

Bioplato Filter Pilot Demonstration Unit

Bioplato filters provide a deep natural water purification in water supply (in getting clean water, suitable for drinking) from river, canal, drip, pond, quarry, reservoir, mine water, or in deep water purification from groundwater aquifers.

- The water is deeply purified in agro-hydrotechnical constructions bioplato-filters with specially selected higher aquatic plants-macrophytes, shrubs, moisture-loving trees, certain species of mosses, fungi, micro-organism-purifiers and enzymes, from "heavy" pollution present everywhere in the surface water sources: biogenic compounds of nitrogen and phosphorus, steam, spar, oil products, heavy metal ions, arsenic, dioxins, pesticide residues, drugs, growth hormones, antibiotics, dyes, colloids of organic and mineral origin, chlorides, sulphates, radionuclides, gases (hydrogen sulphide, radon etc.)

- Waste products of water treatment on bio plateau filters, are accumulated in the form of useful green biomass (useful components of the technology bio plateau, which can be easily used: forage for animals, bioethanol production, getting fuel pellets, obtaining building material, etc., rather than obtaining in parallel with water treatment, salt "tailings", eluate, salt concentrates, sludge and silt, as occurs in other water treatment technologies).

- Water, purified with bioplato-filter phytocomplexes, is partially freed from already present salt "tails" and dosed with useful natural microelements and minerals (natural activation and restoration of water).

- After water treatment on biofoam filters (after phyto-water treatment) the technology of deep additional water treatment is applied, for example, with the use of self-cleaning polystyrene foam and combined clarifiers-filters (with activated polystyrene foam or combined filtering load and with the use of activated suspensions).

- Foam-polystyrene and combined self-cleaning clarifiers-filters can be manufactured, for example, as universal block-modular complexes, suitable for installation "from the wheels", which can include self-cleaning polystyrene filters (low-efficiency compact filters of aqua-as design).

- For pilot-demonstrating station of small capacity (to test the calculated parameters of phyto-water treatment technology and selected unit of water treatment equipment on real waters in real climatic conditions), for example, temporary biofloat filters and research self-cleaning foam filters clarifiers can be used.

- For example, research filtration plants (low-capacity polystyrene foam filters) combined into small or medium capacity module-blocks, additionally equipped with contact clarifiers with a fluidized filtering layer of activated natural suspension (zeolite, brucite, diatomaceous earth, clinoptilolite, etc.) or vortex contact clarifiers can be used as pilot research block-modular facilities. ), or vortex contact bioreactor clarifiers with activated contact loading and foam polystyrene prefilter clarifier, which is determined depending on the initial water parameters and requirements for the quality of treated water.

- Completion of a pilot demonstration phytocomplex of water treatment with bio-plato filter, self-cleaning clarifiers and foam polystyrene research filters for small (medium) capacity stations:

Temporary bioplato filter cascade enclosures are promptly assembled on a prepared earthen (gravel, clay, concrete, etc.) site using prefabricated steel formwork modules (wolf-system formwork).

The diameter of the bioplate filter housing: 12600 mm.

Area of one bio plateau filter: 125 m².

Can be set at a height of 1000 ... 3000 mm for the Bio Plate Filter Casing. (multiple of 1000 mm).

Number of temporary bioplate filter housings: 2...3 modules (up to 5 modules).

Tightness of the bodies of the temporary biofilters is ensured by installing a waterproof membrane lined inside each housing (tent material, or lining the inside with polypropylene sheet).

Filtration loading of temporary biofilters is supplied in the required quantity and with the specified properties after preliminary studies of actual waters and after agreement of the Terms of Reference (ToR).

The minimum volume of activated filtration media to be used (supplied) is 250.0 m³ (20+230 m³). (20+230 m³ according to the specification).

Planting material vvr for temporary biofilters shall be selected and supplied after preliminary studies of actual water and tv.

All utilities are used in a temporary design with flexible hoses, temporary collectors and temporary cable products and temporary control and protection automation.

For dosing of bioreagents and biosuspensions a universal box-dosing unit is used, complete with tanks with working solutions.

Electric power supply to structures and aggregates of demonstration phytocomplex is backed up by electric generator (5...7 kW, depending on conditions of the object).

Planned term of installation of structures and units of pilot-demonstrating phytocomplex to its start in demonstration operation - up to 25 working days (on the assumption of availability on site supplied equipment, block-modules, filtration loads, "green" bioreagents-suspensions, pumping and auxiliary units).

Assumed capacity of pilot-demonstration phytocomplex units 15,0....25,0 (30,0) cu.m./day (with possibility of expansion of capacity in 3...5 times (up to 130,0 cu.m./day) by completion with ready filter aggregates-filters with polystyrene foam or combined loading).

The estimated conditional number of inhabitants served by the pilot water treatment station (as a result of drinking water quality) - up to 300 ... 600 conditional inhabitants, or up to 2600 inhabitants at completion of pilot-demonstration phyto-complex with additional clarifiers-filters.

The basic principles ensuring the efficiency and expediency of the application of synergistic-biotechnical water treatment.

- The capital cost of the treatment plant is lower compared to other treatment methods. The construction and operation of agro-phytotechnical treatment plants makes maximum use of local climatic conditions, local water resources and local operating materials. There is practically no need for imported consumables and chemicals.

- There is no need for highly trained personnel. No complicated water treatment and conditioning control systems. No need for highly skilled personnel to operate and maintain the water treatment systems.

- High plant reliability in the long term, increasing treatment efficiency over time. After construction, the wastewater treatment plant is set up for phytoremediation under real climatic conditions and in real water bodies.

- The high efficiency of nutrient recycling by higher aquatic plants and their productivity makes it possible to use them as a source of useful products. Waste from the water treatment process is transformed into easily recyclable green biomass or dry plant stems suitable for use in construction, heat production, grass meal for animals, bioethanol, cellulose.

- Low operating costs based on comparatively low energy consumption. No use of expensive and energy-intensive complex systems: membrane filters, ion exchange resins, activated carbon, synthetic sorbents, chemical reagents, electro-osmosis and reverse osmosis units, evaporators.

- No need to use reagents for water treatment and disinfection. Autonomous water treatment process, without the use of reagents, electricity and maintenance by operators and technologists, as well as possible frequent interruptions in water supply for treatment and sharp fluctuations in the flow of treated water. Removal of pollutants (including xenobiotics) to regulatory requirements through the use of plant-bacterial communities.

- The construction of WCFs is economically feasible, including in small communities, as it saves costs for the construction of the collector network and pumping stations. WCFs can be built for individual groups of developments without combining wastewater into one large wastewater treatment plant. The technology is easily adaptable to other, already technologically accepted principles and systems of water treatment and can serve for pre-treatment of water before the applied "old" treatment system or for additional treatment of water after the existing treatment plant in order to remove compounds difficult to remove, The treatment plant is designed for additional treatment of compounds difficult to remove in treated water (nutrients of nitrogen and phosphorus, mineral and organic salts, drug residues, pesticides, oil products, fuel impurities, dyes,

- Biogeochemical compatibility with natural landscapes, aesthetic appeal. The process chain is simple to understand and apply and can be learned quite easily by consumers and copied quite easily for use in wastewater treatment plants of any capacity.